CIP Pump-Cleaning In Place Pump Supplier

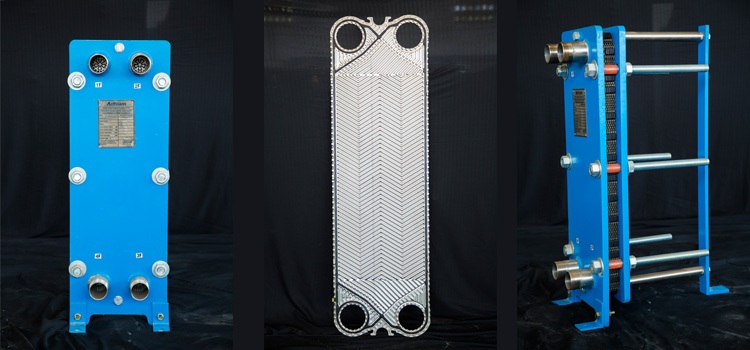

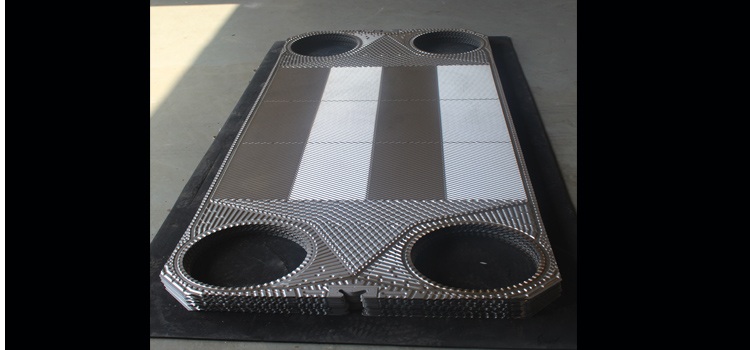

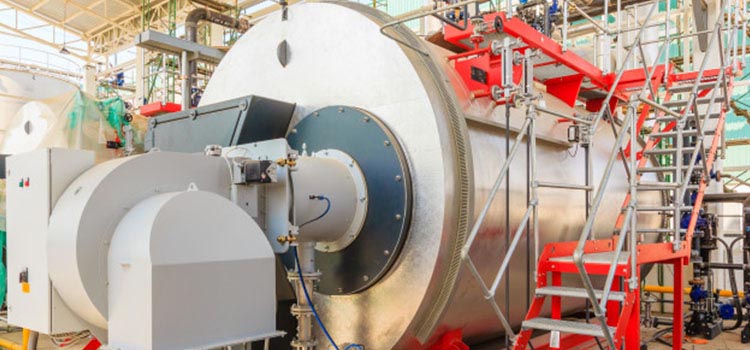

Adhiam is not only servicing with CIP pump , but also manufacture various capacities as per the requirement of customer . We have supplied CIP pump for Sugar Industries in Tamilnadu for regular cleaning of Plate heat exchangers. We are also exporting to Marine companies in abroad with various capacities and with current and Voltage requirement specific to the country.

CIP Pump-Cleaning In Place Pump Supplier Read More »