Forging a Greener Future: Our Journey

From our inception in 2005, we’ve defied norms, pushing the envelope in heat transfer technology. Every project, every innovation, has been a step toward sustainability. At Adhiam, we don’t just make heat exchangers; we create smarter, greener solutions, shaping a future where industry thrives in harmony with the environment.

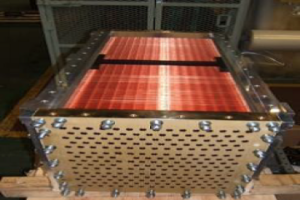

Heat Exchangers Division

Our Heat Exchangers Division revolutionizes industrial efficiency. We design, fabricate, and maintain top-tier heat exchangers. Industries like chemical processing, power generation, and refrigeration rely on our cutting-edge solutions to optimize performance and reduce energy waste. With Adhiam, you get precision-engineered products that redefine heat transfer.

Optimizing Performance, Maximizing Sustainability

Adhiam is equipped to provide complete solutions to prevent marine growth in equipment and pipelines. It’s a general concern of the user as to the quality of the product bought from the market. With our in-depth technical expertise and experience in Electrolyser design, Plant design and Project Execution, Adhiam has the necessary capability to deliver superior value and quality.

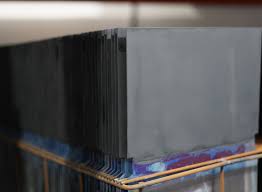

Special Projects Division

Our Special Projects Division takes on the toughest challenges. We design and fabricate skid-mounted fluid cooling and heat recovery systems for diverse applications, including power generation, chemical processing, and oil and gas production. Plus, we excel in solar PV power plants, both on-grid and off-grid. At Adhiam, we transform ambitious ideas into tangible, sustainable solutions.