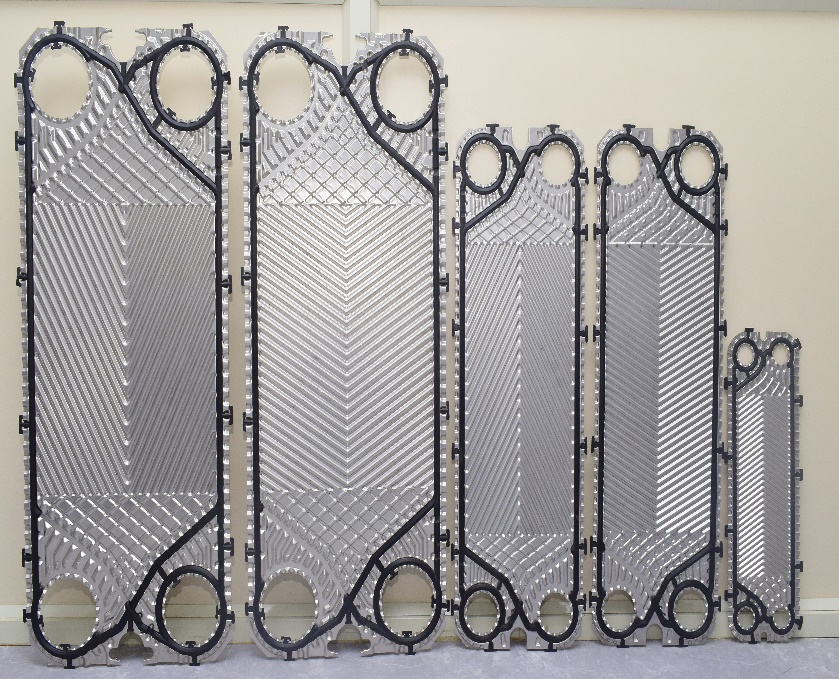

Conventional plate heat exchanger

Conventional plate heat exchanger

Plate heat exchanger consists of corrugated plates fixed with gasket and these are mounted between fixed frame and movable frame , Top and Bottom carrying bar are used for hanging the plates in between frames and the ties rods are used for tightening to the required plate pack. Fluids enter through the connections in the frame and are distributed in between plates. The fluids flow thorough alternate passages between plates by means of gasket arrangement.

EFFIECIENT HEAT TRANSFER DUE TO CORRUGATED PLATES AND THIN MATERIAL.COMBINATION OF HIGH THETA AND LOW THETA PLATES IN THE SAME PLATE HEAT EXCHANGER GIVES DESIRED PRESSURE DROP AND THERMAL PERFORMANCE WITH LESS NUMBER OF PLATES.

Optimum performance is guaranteed

Adhiam specializes in solving various heat transfer problems of our customers by associating ourselves in their design and operation team to many industries such as oil and gas, Edible oil, chemical etc

Specifications

- More than 20 sizes available with every size two to three plate pattern

- Connection size available from 20 mm to 350 mm

- Heat Transfer Area from 0.02 m2 to 1.84 m2 per plate

- Design Pressure up to 25 bar

- Plate MOC: AISI304,AISI316,SMO254, Hastelloy C 276 , Titanium , TI-Pd, Nickel etc

- Gasket MOC : NBR, NBR P, HNBR, EPDM, EPDM -P, Viton A , Viton G etc

Features and Benefits

- Efficient Heat Transfer- Reduced capital cost

- Low Weight—Lower foundation cost

- Flexibility- Easy to alter duties

- Minimised vibration-Longer life time , reliability

- Easily accessible heat transfer Area- lower maintenance

- Close Temperature Approach – Suitable for Heat Recovery and regeneration application with more recovery

Construction Standard:

According to PED 97/2/EC: A-D” Merkblatter”

- According to ASME CODE: ASME VIII, DIV.1

Applications

Lean amine vs Rich amine – heat recovery

- Lube oil cooling

- jacket water engine cooling

- Heating and cooling chemicals

- Waste heat recovery from condenser water

- Heating and cooling syrub/milk/corbonated water etc

- Waste heat recovery

- Heating and cooling process fluid

- Cooling of Anodising solution

- Cooling of quench oil

- Acid coolers

- Waste heat recovery

- Turbine cooling

- Heat recovery in boiler blow down

- Lube oil cooling

- Chilled water cooler

- Cooling machine oil

- Cooling grinder coolant

- Cooling electronic equipments

- Raw juice heating

- Clear juice heating

- Molasses cooling