Free Flow Wide gap plate heat exchanger

Construction

Free Flow Wide gap plate heat exchanger

Plate heat exchanger consists of corrugated free flow plates fixed with gasket and these are mounted between fixed frame and movable frame, Top and Bottom carrying bar are used for hanging the plates in between frames and the ties rods are used for tightening to the required plate pack.

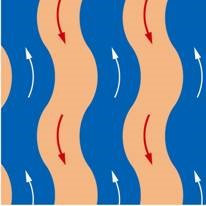

Fluids enter through the connections in the frame and are distributed in between plates. The fluids flow thorough alternate passages between plates by means of gasket arrangement. Due to more gap, the gasket groove is deeper and the thickness of the gasket is more.

- Connection size available from 50 mm to 200 mm

- Design Pressure up to 25 bar

- Plate MOC: AISI304,AISI316,SMO 254 etc

- Gasket MOC : NBR, NBR Peroxide cured, HNBR, EPDM, EPDM -P etc

Features

- No / very few metal-to-metal contact points in the flow channels.

- Up to 12mm plate gap.

- Trouble-free operation for product containing: solids / particles, pulps & fiber, viscous products

Benefits

- Gentle treatment of heat sensitive products

- Improve plant economics

- shorter Cleaning-In-Place cycle

- extend production run time

Application

Free flow wide gap plate heat exchangers shall be used where conventional gasket type plate heat exchangers meet their limitation. This can be used for Heavy contaminated fluids, Liquids containing solids, and viscous Products.