MMO Anodes

MMO Coating On Titanium

MMO anodes are used in Cathodic Protection (CP) and has wide applications due to its significant advantages such as

- Reliability

- Exceptionally long life

- Available in numerous anode configurations

- Light weight

- Low cost

MMO anodes have imperceptibly low wear rates and are dimensionally Stable Anodes as they do not change geometry over time.The coating recipe consists of an electro catalytic conductive component that catalyzes the reaction to generate current flow, and bulk oxides that prevent corrosion of the substrate material.

Ruthenium Oxide (RuO2)

Ruthenium oxide, which is the cheaper of the two electrocatalysts, should only be used in chlorinated environments (sea water). The catalytic life is significantly reduced when the primary reaction is the evolution of oxygen (fresh water, soil, coke backfill and concrete environments).

Iridium Oxide (IrO2)

Iridium Oxide based mixed metal oxide for their cathodic protection anodes because it is suitable for both chlorinating and oxygenating environments. The bulk oxides are typically a mixture of Titanium Dioxide (TiO2) and Tantalum Oxide (TaO5). Their primary purpose is to provide an oxide film over the substrate material to prevent corrosion of the substrate.

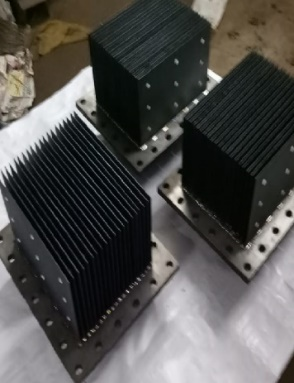

MMO coated Titanium Anode

Mixed metal oxide anodes are applied over a commercially pure titanium substrate.

Advantages

- Titanium is readily available in commercially pure form

- Excellent adherence properties with proper surface preparation

- Lightweight

- Outstanding mechanical strength

- Outstanding chemical resistance to highly acidic conditions – typical for oxygen and chlorine evolving environments common in many cathodic protection applications.

Platinum coated Anode

Platinum is noble metal and have high conductivity, chemically stable and highly resistant to Oxidation and corrosion. Due to its high cost, the coating is being done on metal like titanium , tantalum , Niobium. Among these three metals, titanium is less expensive.Depends on the current rating and applications, the metal can be chosen.platinized titanium anodes : recommended operating voltage is 8 V. The corresponding maximum current density output is approximately 1 kA m-2.when operating voltages are relatively high, niobium and tantalum based anodes are generally selected.